Pilot value chains

The Videometer Spectral Imaging Technology is one very promising and already validated efficiency in prediction of quality and safety technologies in the food domain. The VideometerLite technology that will be developed in the TraceMyFish project will be tested within three value chains.

- The Atlantic Salmon value chain in Norway

- The Atlantic whitefish value chain in Iceland

- The Mediterranean Seabream/Seabass value chain in Greece

Videometer Spectral Imaging Techniques in TraceMyFish

The, very promising, Videometer Spectral Imaging technology is non-destructive, allowing the detection of hazards and quality related issues as well as a product’s chemical and physical structure.

Videometer spectral imaging instruments measures more than 12 million individual spectra on a food sample within a few seconds (7-8 seconds), in a structure of a data cube, several spectral planes (7 different wavelengths) where each plane reflects a monochromatic image at a specific wavelength. Every pixel in the image is a spectrum covering UV, visual color, and NIR ranges, including a fluorescence option, and of areas down to 65×65 µm.

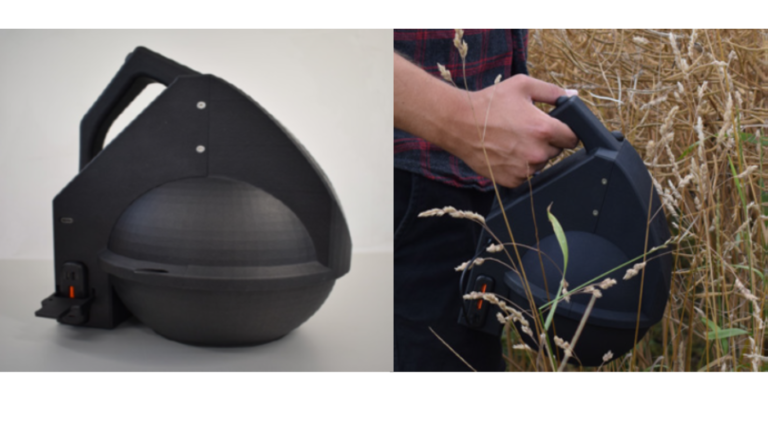

The analytical power of the technology offers a unique potential for fast characterisation of food integrity in terms of color, surface chemistry, texture, shape, and size without touching the sample and with little or no sample preparation. In the TraceMyFish project, Videometer will provide a modified version of the VideometerLite system (VideometerLite – Videometer), shown in Figure 1, that will be used to collect data as input for the TraceMyFish iFMS. VideometerLite is a portable and wireless spectral imaging device designed for easy, straightforward, and accurate image analysis.

With its state-of-the-art technology, the instrument allows for the determination of colour, texture, and surface chemical composition of up to 100×100 mm of sample size. Using strobed LED systems, VideometerLite efficiently combines the measurements of seven wavelengths into a single spectral image, where each pixel corresponds to a different reflectance spectrum, wavelength range [405-850 nm] – nonuniformly distributed. Thus, it includes both visual and NIR wavelengths for a precise, accurate, and thorough quality inspection foods.